Tests and Certificates

Tests

Each equipement manufactured is tested according to "Routine verification" defined in chapter 11 of CEI 61439-1 standard.

The test report "Control procedure" according to our internal procedure Ref FCG101 is supplied to the curstomer as well as CE marking compliance certificate.

Each equipement file is kept for 20 years.

Original manufacurer design tests

Tests : a key point for a system like TABULA

Type tests include :

-

IEC/EN 61439-1 and 2

-

IEC/EN 61439-3

-

Test reports and certificates

-

Performed by international laboratories KEMA, ASTA, NEFI, aso.

-

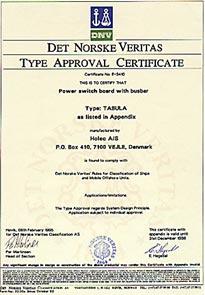

Certified by the DNV

-

A detailed documentation is available to Tabula switchboard manufacturers

Type tests include :

a) Resistance to corrosion

b) Thermal stablity

c) Resistance to abnormal heat and fire due to internal electric defects

d) Resistance to UV radiation

e) Lifting

f) Degree of protection of enclosures

g) Clearance

h) Creepage distance

i) Effective continuity between the exposed conductive parts of the assembly and the protective circuit

j) Effectiveness of the assembly for external faults

k) Power frequency widstand voltage

l) Impulse widtstand voltage

m) Temperature-rise limits

n) Short-circuit widstand strength

o) Electromagnetic compatiblity

p) Mechanical operation

TABULA has been certified with the following equipment brands:

- ABB

- SCHNEIDER

- EATON

Internal arcs

TABULA has been tested with most severe arc spécifications (secondary and primary) according to :

SEK 405, AS 1136 1, IEC 298 et PEHLA

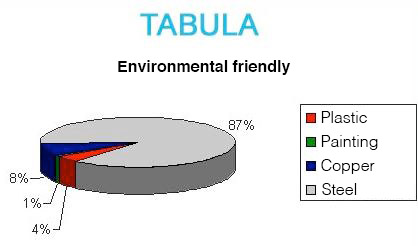

Environment

An activ environment policy

-

Certificate "Green Network"

-

Tabula commitment

-

Each material is clearly documented

-

Minimum dammage to environment